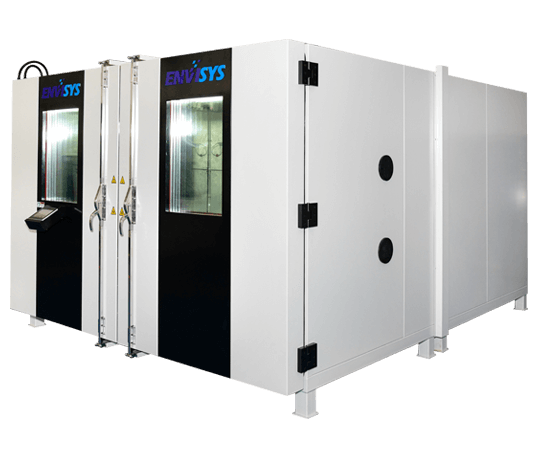

Standard Volumes 150,300,600,950&1400 Liters Temperature -40 / -70 ℃ to 180 ℃ +/-1℃ Relative Humidity 10% to 95% +/- 3%

- Communication ports viz., RS-232, RS-485, USB, Ethernet and USB host port.

- On board 256 MB user memory and extender SD card up to 2 GB memory for data and program storage.

- Direct real time trend capture and storage provision on the controller.

- On demand Auto Tuning.

Volume 150,300,600,950&1400 Liters

Temp -40 / -70 to 180℃

Humidity: 10 to 95% RH

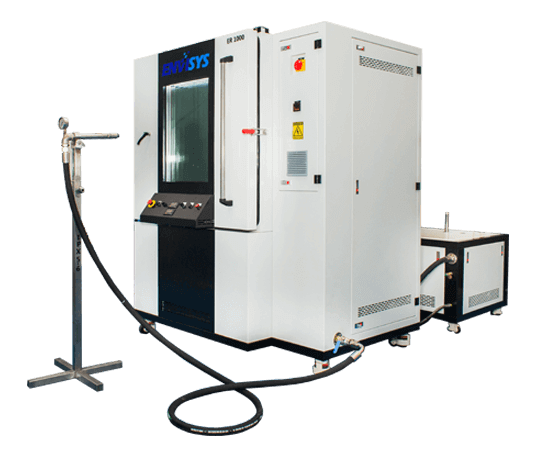

- Bottom of the chamber will have specially designed interchangeable hood with interface mechanism to couple the shaker and chamber during combined tests.

- Chamber will be moved up and down vertically through friction-free guided U channel and wheel.

- Chamber will be moved horizontally manually using heavy duty castor wheel with railing.

- ET-touch color touch programmer.

- RS-232, RS-485, USB, Ethernet and USB host port.

Standard Volumes 150,300,600,950&1400 Liters

Temperature -40 / -70℃ to 200℃ +/- 1℃

Basket Transition Time < 10 Secs

- Colour touch programmer with built- in web server that allows remote monitoring and operation of your chamber from any Internet connected PC or smart phone.

- Communication ports viz., RS-232, RS-485, USB, Ethernet and USB host port.

- Onboard 256 MB user memory and extender SD card up to 2 GB memory for data and program storage.

- Direct real time trend capture and storage provision on the controller.

- Total programming capability up to 99 programs.

- 3 User programmable soft keys with LED indication for pre-assigned functions.

- Test data storage of individual file and folder wrt time.

- Graphical programming for faster programming and program view.

- Real time trend available with user scaling.

- On demand auto tuning.

- Three level security for different user access.

AVAILABLE RANGE: 600, 950 AND 1400 LITRES Temperature -40 / -70℃ to 180℃ Relative Humidity: 10% to 95% (optional) Altitude: Up to 10 m bar

- ET-touch color touch programmer.

- RS-232, RS-485, USB, Ethernet and USB host port.

- Height adjustable specimen racks.

- Cable ports.

- Built-in web server which allows remote monitoring

Volume 10000,12000,14000, 16000, 18000 & 22000 Liters Temp Relative Humidity -35 / -65 to 180℃ 10 to 95% RH

- ET-touch color touch programmer

- RS-232, RS-485, USB, Ethernet and USB host port

- Height adjustable specimen racks

- Cable ports

- Built-in web server

ENVIRONMENTAL CHAMBER FOR UNIVERSAL TESTING MACHINE

- Temperature-Rh-Salt Fog Integrated Test Equipment For UTM Interface

- ETU-Series Environmental Test Chamber for conducting environmental tests at elevated and freezing temperatures in order to perform integrated tests for hot & cold conditions on universal testing machines.

- Temperature-Relative Humidity-Salt Fog Integrated Test Apparatus for UTM Interface is designed to meet

AVAILABLE RANGE: 600, 950 AND 1400 LITRES Temperature: -40 / -70 C to 180 C RH: 10% to 95% (optional)

- Environmental Chambers for Battery Testing are designed and manufactured to meet various types of battery testing requirements of its customers by keeping all safety options in mind against any harmful explosions or ignitions and user safety while testing these batteries for environmental stress conditions

Standard Volumes 300,600,900 & 1500 Liters Chamber Temp Adjustable from ambient to 50℃ Saturator Temp Adjustable from ambient to 65℃ Saturation / Controlled Humidity - optional

- Fine-fog simulation atomizer.

- Regulated humidity/saturation tower for producing saturated humid air.

- Low-density ceramic layer rope-heaters bonded outside the tank with aluminium foil rapping for uniform conduction of temperature.

- Hanging rods and slotted angle racks for hanging/placing the specimen.

- Maintenance free independent removable brine solution reservoir tub.

INDUSTRIAL CHILLLERS AND OVENS

Eco-friendly refrigerant Hermetic scroll/reciprocating compressors. Finned coil Condenser with copper tubes and aluminium fins. Axial fans di-casted with aluminium and crescent shaped blades. BPHE for evaporation. Storage tank with filling/drain valves, pump and pressure gauge. Level sensors.Low/High refrigerant pressure switches.

Liquid ingress Protection Test Chambers Designed to meet Ingress Protection Standards. Built to the requirement from component level testing, room level testing to field testing of large sized products. High quality corrosive resistance material for construction. Drip-tank designed and manufactured to meet the desired fall-rate as per standards. Spray and Jet nozzles are manufactured in single operation CNC with high dimensional accuracies.Highly reliable water circulation pump and pipeline. Vibration-free rotating table with variable speed control. Full-view glass door with wiper.